Liquid and Immersion Heater Inquire Table

In the table below

- P : represents PTFE Heater

- S : represents Standard Steel Heater

- 4 : represents 304 Stainless Steel Heater

- T : represents Titanium Heater

- Q : represents Quartz Heater

- 6 : represents 316 Stainless Steel Heater

If there is an asterisk(*) in the upper right corner, it means that the heater is a low-power version heater.

The information listed below is for reference only and should not be used as the basis for design specifications and limitations. Due to the wide variety of heated solutions and diverse applications, please consult professionals familiar with chemical properties or contact us directly before making a selection.

Please note that the immersion heaters are strictly prohibited for use with flammable solutions.

Improper installation and maintenance can cause combustion of plastic materials such as P.P. and P.E., and pose an electric shock hazard to personnel.

| Heated solution | Heater |

|---|---|

| Chromium(No Fluorides) | P、Q、T |

| Chromium(No Fluorides) | P、Q、T |

| Citric Acid | T |

| Clear Chromate | P、Q |

| Cobalt Nickel | P、Q、T |

| Cobalt Plating | 4 |

| Cobra Etch | P |

| Copper Acid | P、Q |

| Copper Bright Acid | P、Q |

| Copper Cyanide | 4 |

| Copper Bright Acid | P、Q |

| Copper Cyanide | 4 |

| Copper Fluoborate | P |

| Copper Pyrophosphate | 4 |

| Copper Strike | 4 |

| Copper Sulfate | P、Q |

| Cyanide | 4 |

| Deionized Water | 6 |

| Deoxidizer(Etching) | Q |

| DeoxidizerNon-Chromated | 6 |

| Dichromic Seal | S |

| Diethylene Glycol | 4 |

| Diversey,511,514 | P |

| Dow Therm | 6* |

| Dye Solution | 4 |

| Ebonal C | T |

| Electroless Copper | P |

| Electroless Nickel | P*、T* |

| Electroless Tin(Acid) | P、Q |

| Electroless Tin(Alkaline) | 6 |

| Electro Cleaner | 4 |

| Electro Polishing | P、Q |

| Enthone 80 Acid | P |

| Ethylcne Glycol | S* |

| Ferric Nitrate | 4 |

| Ferric Sulfate | 4 |

| Ferric Ammonium Oxide | 6 |

| Ferric Chloride | P、Q、T |

| Fluborate | P |

| Heated solution | Heater |

|---|---|

| Silver Bromide | 6 |

| Silver Cyanide | 4 |

| Silver Lume | 4 |

| Silver Nitrate | 6 |

| Sodium Bisulfate | P、Q |

| Sodium Carbonate | T |

| Sodium Chlorate | T |

| Sodium Chloride | T |

| Sodium Cyanide | 4 |

| Sodium Dichromate(Hot Seal) | 6 |

| Sodium Hydroxide | S |

| Sodium Hypochlorite | P |

| Sodium Persulfate | P、Q |

| Stannate | S |

| Stanostar | P、Q |

| Stearic Acid | Q |

| Sulfamate Nickel | P、Q、T |

| Sulfur | P、Q |

| Sulfuric Acid | P、Q |

| Sulfur Peroxide | P、Q |

| Sulphamic Acid | P、Q |

| Tannic Acid | T |

| Tin Nickel | P |

| Tin Plating(Acid) (Stanus/Sulphate) |

P、Q |

| Tin Plating(Acid)(Fluoborate) | P |

| Tin Plating(Alkaline) | 4 |

| Trichlorocthylene | 6* |

| Trioxide(Pickle) | P、Q |

| Turco(4181,4338) | 6* |

| Unichrome | P、Q |

| Water | 6、Q |

| Wood's Nickel Strike | P、Q、T |

| Yellow Dichromate | P、Q |

| Zinc Acid | P、T |

| Zinc Ammonium Chloride | Q、T |

| Zinc Cyanide | 4 |

| Zinc Phosphate | 6* |

| Zincate | 4 |

| Substance | kcal/kg | g/cm | kcal/kg | ℃ |

|---|---|---|---|---|

| Substance | 0.23 | 2.7 | 77 | 660 |

| Antimony | 0.05 | 6.8 | 14 | 630 |

| Bismuth | 0.031 | 9.8 | 12.5 | 270 |

| Brass | 0.1 | 8.7 | 920 | |

| Copper | 0.1 | 8.9 | 42 | 1080 |

| Steel | 0.12 | 7.8 | 49 | 1399 |

| Cast Iron | 0.13 | 7.2 | 1260 | |

| Wrought Iron | 0.12 | 7.5 | 1538 | |

| Lead (Solid) | 0.031 | 11.34 | 6.3 | 327 |

| Lead (Dissolved) | 0.04 | |||

| Tin (Solid) | 0.056 | 7.3 | 14.6 | 231 |

| Tin (Dissolved) | 0.064 | |||

| Solder | 0.04 | 9.3 | 9 | 215 |

| Type Metal | 0.04 | 10.7 | 260 | |

| Zinc | 0.095 | 7.1 | 28 | 420 |

| Nickel | 0.11 | 8.8 | 74 | 1450 |

| Silver | 0.057 | 10.6 | 20 | 960 |

| Gold | 0.031 | 19.32 | 16 | 1063 |

| Stainless Steel 18.8 | 0.11 | 7.82 | 64 | 1430 |

| Platinum | 0.032 | 21.45 | 27 | 1773 |

| Nickel Chromium | 0.1 | 8.67 | 70 | 1400 |

| Manganese | 0.11 | 7.87 | 47 | 1247 |

| Pewter | 0.09 | 8.7 | 900 | |

| Asphalt | 0.4 | 1 | 22 | 120 |

| Paraffin Wax | 0.7 | 0.9 | 35 | 54 |

| Tungsten | 0.033 | 19.35 | 3380 | |

| Bakelite | 0.38 | 1.27 | ||

| Rubber | 0.270.48 | 0.921.23 | ||

| Paper | 0.45 | 0.9 | ||

| Glass | 0.186 | 2.59 | ||

| Quartz | 0.174 | 2.21 | ||

| Mica | 0.21 | 1.92.3 | ||

| Concrete | 0.2 | 2.63.2 | ||

| ֺSilica Bricks | 0.24 | 2.0 | ||

| Asbestos | 0.19 | 0.47 | ||

| Rockwool | 0.24 |

| Substance | kcal/kg | kg/m |

|---|---|---|

| Acetylene | 0.35 | 1.12 |

| Air | 0.237 | 1.28 |

| Alcohol | 0.453 | |

| Ammonia | 0.52 | 0.64 |

| Argon | 0.124 | 1.6 |

| Carbon Dioxide | 0.203 | 1.92 |

| Carbon Monoxide | 0.243 | 1.12 |

| Chlorine | 0.125 | 3.2 |

| Ethylene | 0.4 | 1.12 |

| Hydrochloric Acid | 0.195 | 1.6 |

| Hydrogen | 3.41 | 0.089 |

| Methane | 0.6 | 0.71 |

| Chloromethane | 0.24 | 2.09 |

| Nitrogen Chloride | 0.231 | 1.24 |

| Nitrogen | 0.245 | 1.24 |

| oxygen | 0.218 | 1.44 |

| Sulfur Dioxide | 0.155 | 2.86 |

| Substance | kcal/kg | g/cm | kcal/kg | ℃ |

|---|---|---|---|---|

| Alcohol | 0.65 | 0.9 | 200 | 77 |

| Volatile Oil | 0.45 | 0.9 | 90 | 82 |

| Ether | 0.503 | 0.7 | 88 | 35 |

| Ammonia | 1.146 | 0.61 | 284 | |

| Ethylene Glycol | 0.57 | 1.1 | 240 | |

| Glycerol | 0.58 | 1.3 | 288 | |

| Mercury | 0.033 | 13.5 | 64 | 360 |

| Vegetable Oil | 0.47 | 1.0 | ||

| Olive Oil | 0.47 | 0.9 | 299 | |

| Paraffin Oil (Dissolved) | 0.71 | 0.9 | 399 | |

| Petroleum | 0.51 | 0.9 | ||

| Turpentine | 0.41 | 0.9 | 73 | 160 |

| Spindle Oil | 0.44 | 0.87 | ||

| Transformer Oil | 0.45 | 0.86 | ||

| Water | 1 | 1.0 | 530 | 100 |

Engineering-plastics Properties Reference Table

| Properties | MC | PA | UPE | PE | PTFE |

|---|---|---|---|---|---|

| Monomer Casting Nylon | |||||

| Proportion | 1.2 | 1.41 | 0.94 | 0.93 | 2.2 |

| Water Absorbency | 1.8 | 0.22 | 0.01 | 0.01 | 20.01 |

| Hardness | D80 | D85 | D78 | D68 | D55 |

| Impact Strength | 50 | 19.1 | Not destroyed | 20 | 2.8 |

| Coefficient of Friction | 0.15 | 0.18 | 0.03 | 0.18 | 0.04 |

| Tensile Strength | 850 | 620 | 450 | 250 | 250 |

| Thermal expansivity | 9 | 9 | 10 | 11 | 8.5 |

| Coefficient of thermal conductivity | 0.2 | 0.2 | 12 | 0.21 | 60 |

| Heat Deflection Temperature | 180℃ | 120℃ | 135℃ | 90℃ | 280℃ |

| Heat Resistance Temperature | 135℃ | 110℃ | 120℃ | 80℃ | 260℃ |

| Degree of Insulation Breakdown | 350 | 500 | 710 | 500 | 480 |

| Acid-base Strength | Weak | Strong | Weak | Weak | Strong |

| Acid-base | Acid-base | Acid-base | Acid-base | Acid-base |

| Properties | PU | Insulating board | PEEK | VESPEL | PETP |

|---|---|---|---|---|---|

| Proportion | 1.2 | 1.4 | 1.3 | 1.41 | 1.38 |

| Water Absorbency | 0.8 | 0.65 | 0.14 | 0.21 | 0.07 |

| Hardness | M-R | D35 | D86 | R126 | D87 |

| Impact Strength | Not destroyed | 35 | 45 | 1.6 | 25 |

| Coefficient of Friction | 0.38 | 0.1 | 0.02 | 0.03 | 0.25 |

| Tensile Strength | 700 | 1000 | 990 | 950 | 800 |

| Tensile Strength | 15 | 2.5 | 4.8 | 4.6 | 7.5 |

| Coefficient of thermal conductivity | 5 | 3 | 0.6 | 0.36 | 0.24 |

| Heat Deflection Temperature | 110℃ | 180℃ | 252℃ | 500℃ | 115℃ |

| Heat Resistance Temperature | 90℃ | 140℃ | 240℃ | 480℃ | 100℃ |

| Degree of Insulation Breakdown | 530 | 12 | 19 | 80 | 60 |

| Acid-base Strength | Weak | Weak | Strong | Strong | Strong |

| Acid-base | Acid-base | Acid-base | Acid-base | Acid-base |

Applicable Tube Materials and Unit Conversion Table

Applicable Tube Materials

| General/Neutral | Copper sus304 316 tubes |

| Weak Acid/Weak Base | Nickel Alloy tubes |

| Moderate Acid/Base | Titanium Alloy tubes |

| Strong Acid/Strong Base | Quartz/PTFE |

Length Conversion Table

| cm | m | Taiwanese foot (unit of length) | inch | ft | mile | km |

|---|---|---|---|---|---|---|

| 1 | 0.01 | 0.033 | 0.3937 | 0.03281 | 1 | 1.6093 |

| 100 | 1 | 3.300 | 39.37 | 3.281 | 0.6214 | 1 |

| 2.540 | 0.0254 | 0.0838 | 1 | 0.08383 | ||

| 30.48 | 0.3048 | 1.0058 | 12 | 1 |

Volume Conversion Table

| L | m3 | cm3 | in3 | U.S.gal | Emp.gal |

|---|---|---|---|---|---|

| 1 | 0.001 | 1,000 | 61,0200 | 0.264170 | 0.219975 |

| 1,000 | 1 | 1,000,000 | 61,020 | 264,170 | 219,975 |

| 0.001 | 0.000001 | 1 | 0.061020 | 0.000264 | 0.000219 |

| 0.016387 | 0.0000164 | 16,387 | 1 | 0.004329 | 0.003605 |

| 3.78543 | 0.003785 | 3,785.43 | 231 | 1 | 0.832699 |

| 4.54596 | 0.004546 | 4,545.92 | 277,427 | 1201 | 1 |

Area Conversion Table

| are | m2 | cm2 | in2 | Ping (unit of area) | ft | acre |

|---|---|---|---|---|---|---|

| 1 | 100 | 1,000,000 | 155,000 | 30.250 | 1,076.39 | 0.024710 |

| 0.01 | 1 | 100,000 | 1,550 | 0.3025 | 10.7639 | 0.000247 |

| 0.000001 | 0.0001 | 1 | 0.1550 | - | 0.001076 | - |

| 0.000006 | 0.000645 | 6.5420 | 1 | - | 0.006944 | - |

| 0.000928 | 0.92899 | 928.99 | 144 | 0.02810 | 1 | 0.000022 |

| 40.47 | 4,046.87 | - | - | 1,224.17 | 43,560 | 1 |

Weight Conversion Table

| t | kg | g | Taiwanese catty (unit of weight) | 1b | s.t. | L.t |

|---|---|---|---|---|---|---|

| 1 | 1,000 | 1,000,000 | 1,666.66 | 2,204.62 | 1.1023 | 0.984205 |

| 0.001 | 1 | 1,000 | 1.666 | 2.20462 | 0.001102 | 0.000984 |

| 0.000001 | 0.001 | 1 | 0.0016 | 0.002204 | 0.000001 | 0.0000009 |

| 0.000453 | 0.453592 | 453,592 | 0.75598 | 1 | 0.0005 | 0.000446 |

| 0.907185 | 907.185 | 907,185 | 1,511.97 | 2,000 | 1 | 0.892857 |

| 1.01605 | 1,016.05 | 1,016,047 | 1,693.41 | 2,240.00 | 1.12 | 1 |

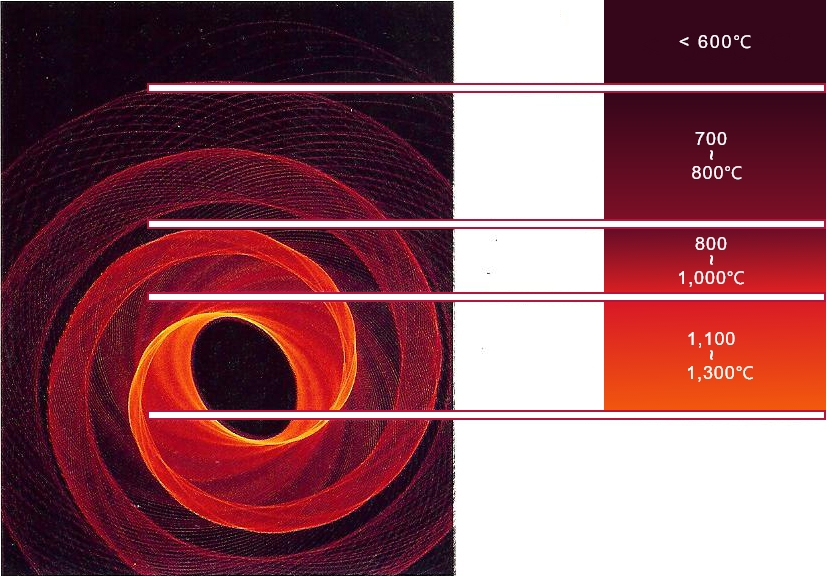

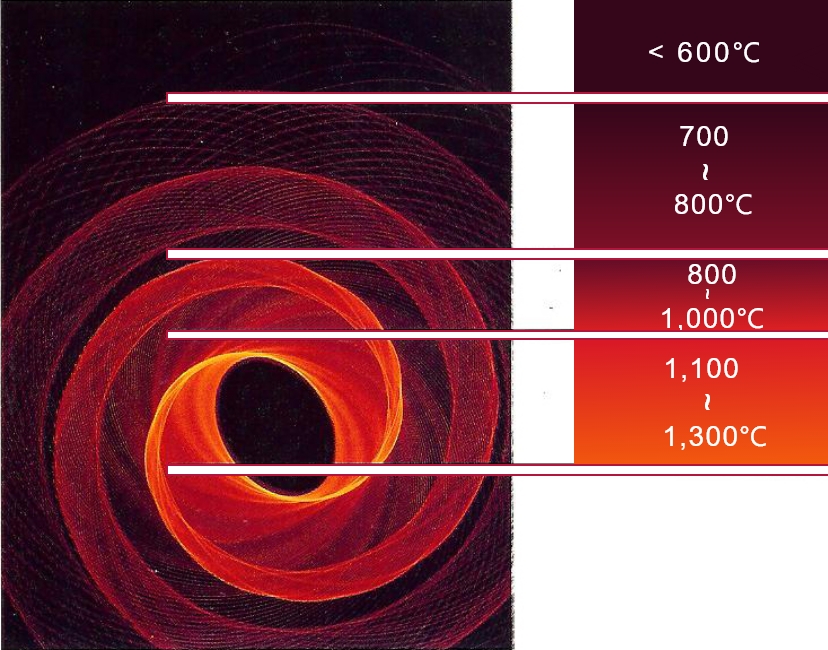

Visual Temperature Chart